Craig M Baudendistel, Ph.D.

Important Links

- Install Solidworks

- Install Matlab

- Matlab Course Videos

- Solidworks Basics Videos

- Solidworks Certification Website

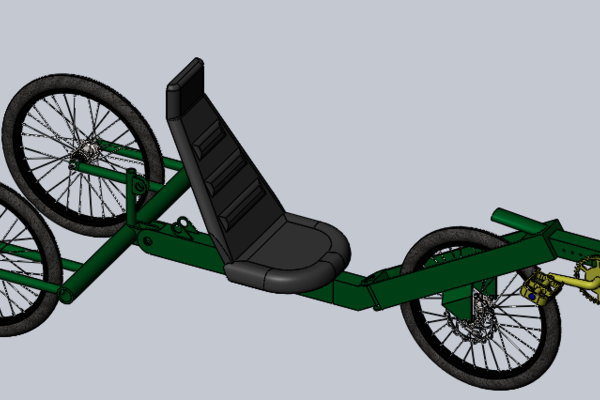

- SAE Baja Presentation

- STEM Baja Frame

Updated 08/2025

I am a non-tenure eligible (NTE) Lecturer for the Mechanical and Materials Engineering Department. I teach a number of first year classes for (mostly) mechanical engineers, but quite honestly these couple classes would be beneficial for all engineering disciplines. I truly enjoy teaching these classes because skills like CAD, programming, and applied mathematics give students tangible skills that employers are looking for right away (for ALL disciplines). Apply for that internship/co-op as soon as possible!

Advice for undergraduates:

While your main goal is to earn a B.S. degree, you should always be thinking of ways to stack your resume such that yours stands out when it comes to getting a job or going to graduate school. This can be done with extracurricular activities, honors societies, or memberships to professional organizations. Serve these groups as a leader and put it on your resume. Pick up a teaching job during undergrad. Not only will it solidify *your* skills, you'll probably be paid a bit to help other students. This also looks good on a resume. Lastly, get an internship early and try different kinds out - such as governement, private industry, large/small companies. Nobody cares if you had 3 different internships and it will give you a taste of the different job types. Always take at least one class and work full time at your internship during the summers. This will ease the course load in your senior year and provide extra time to put towards your senior capstone project or even more hours at work if you need it.

Advice for your career:

In my opinion, a B.S. degree is the new high school diploma and employers will expect this in the engineering field. If you want to stand out and possibly move up the ranks more quickly, an M.S. degree is helpful. Should you choose employment right away, negotiate tuition assistance and let your employer know you are interested in an advanced degree (whether in engineering or even business!). Should you choose graduate school right away, do not pay tuition! Either apply for scholarships/fellowships that pay tuition/stipend or find that faculty member you liked in class and ask them if they have any research funding.

Also, if you find you like the practical aspects of engineering more than the theoretical, don't discredit jobs related to the field such as machining, operating technician, aircraft mechanic, CAD drafting, etc. These don't require a 4 year degree, also pay pretty well, and you'd be working in a similar field.

Personal Interests:

I've been playing sand volleyball for over 20 years and in leagues currently at MVS in Miamisburg. My wife and I have renovated 4 houses and a condo over the years. I do most of the work myself, so I'm somewhat familiar with the basics of framing/electrical/plumbing/gas. Current project is finishing my basement and two future additions. I have two young daughters (3 and 8), 30 chickens, and a husky. My wife teaches art classes at Dayton Christian and is a tiling pro.

Service

Because I teach CAD and CAM, I've become familiar with a number of useful machines. In my opinion, engineers ought to have a feel for how these work as their designs will need to be created at some point, typically on these machines. I've compiled a list of items that are available to students for use. Please contact me or Doug Yost (107 RC or doug.yost@wright.edu) if you want access/training on these machines at any point in your tenure here at WSU, even if just for fun.

*Lastly, things do go wrong! It's ok. If you somehow think you broke/damaged a machine, don't fret. Just let me know so we can fix it. No worries! It's part of learning.*

Department Resources:

Tormach 440 PCNC Mill (3x): these are in 014 RC and part of our Capstone Design space. Use Solidworks CAM to generate g-code.

Tormach 8L Lathe (3x): these are in 014 RC and part of our Capstone Design space. Use Solidworks CAM to generate g-code.

Prototrak CNC Knee Mill: this is down in the machine shop in the basement so access is a bit more limited, but it's a great machine to play with. This is a full 3-axis programmable mill that will cut any number of materials. This is a step or two larger than our Tormachs. You can use Solidworks to create g-code that runs this machine.

AccuteX Wire EDM: this machine uses a 0.010" brass wire to electrically cut through almost any conductive material (typically steel/aluminum/inconel). Models are typically created in Solidworks and exported to Esprit CAM software for g-code generation.

Full Spectrum 80W CO2 Laser Cutter/Engraver: this is down in 018 RC in the Capstone Design space. While this will *not* cut metal, it will easily cut 2D shapes out of up to 0.5" plywood/acrylic/cardboard. It will also engrave/etch in metal as well. Use this to build mockups/prototypes for course projects. Download Legacy RetinaEngrave v1.0 to import raster/vector files. Your computer needs an ethernet port to connect to the laser.

Prusa MK4S 3D Printer (4x): These are down in 018 RC and are available to all students who want to try 3D printing. It's cheap and easy. Import your Solidworks CAD file (*.stl) into PrusaSlicer to generate g-code for these machines. Use the provided thumb drive (or your own) to transfer files from your computer to the printer. I'm also a fan of Bambulabs printers and some Creality printers.

One of the Prusa's has the Multi Material Head as well (MMU). If you'd like to use, just let me know and I can help!

Resin 3D Printer: we have one in the additive mfg lab. It's a bit more expensive to use so it doesn't see a lot of use. These can typically hold better tolerances than a FDM printer, but are more....messy.

MIG/TIG welder: this is in the SAE Baja lab. This is obviously useful for metalworking. We need to let campus safety know when we use it, but it is generally available.

Pipe/Tube Bender: this in in the SAE Baja lab. This will bend 1-1.25" steel tubing for structural type applications. We use it mainly for roll cage design for SAE Baja.

Teaching

ME 4160 - Advanced CAD/CAM

ME 4910/4920 - Capstone Design I/II

ME 4140 - Mechanical Design I

ME1040 - Engineering Design with Solidworks

ME 1020 - Engineering Programming with Matlab

EGR 1010 - Introductory Mathematics for Engineering Applications

EGR 1980 - Preparatory Mathematics for Engineering Applications

Consulting

In addition to teaching, WSU allows faculty to consult with external companies to provide engineering expertise in a wide variety of fields. I was lucky enough to work with a small start-up called Drone Express (Discover the Future of Delivery: Drone Technology and Innovation - DEXA). These guys are on the cutting edge of drone package delivery. I started as a CAD engineer and transitioned to their initial design engineer. I got the chance to work with some excellent drone pilots to design a custom air frame from the ground up. I was able to gain skills in RC components, Fusion360, CNC programming with a Carbide 3D router, and Prusa 3D printers, all of which are used to manufacture these drones. Extremely fun project!

Education History

B.S. Mechanical Engineering, Wright State University, 2005

M.S. Mechanical Engineering, Wright State University, 2008

Ph.D. Engineering, Wright State University, 2013

Research Statement

My job does not require a research component. I chose this purposefully as that was not something in which I found joy (ha). While more applied or educational research is interesting to me, my passion is teaching and project-based learning.

Professional Affiliations/Memberships

Society of Automotive Engineers (SAE)

Tau Beta Pi - Engineering Honors Society

Awards/Recognition

CECS Faculty Excellence Award: Excellence in Teaching 2021

Presidential Award for Excellence: Outstanding NTE Lecturer 2021

Outstanding Lecturer Runner-Up, CECS 2020

Outstanding Lecturer Nomination, CECS 2018

CECS Faculty Excellence Award: Outstanding Instructor 2018

Outstanding Lecturer Nomination, CECS 2017

University Presidential Award for Excellence: Outstanding Instructor 2016

SOCHE Outstanding Faculty Excellence Award 2016

Outstanding Lecturer Nomination, CECS 2016